Powder Blending and Transfer

Increasingly, parenteral products are produced in powder form.ATEC has developed systems for safe powder handling and transfer to the filling line.

Increasingly, parenteral products are produced in powder form.ATEC has developed systems for safe powder handling and transfer to the filling line.

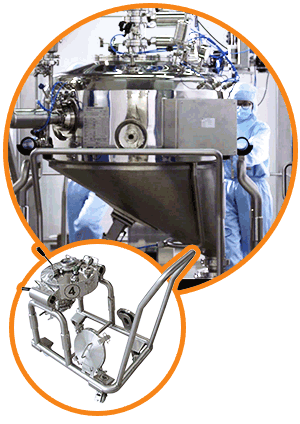

Complete solutions for powder transfer

Profitability, sterility of the powder and collaterals - both of the customer's employees and those of the active pharmaceutical ingredient - pose major challenges to the practice of powder transfer. ATEC Pharmatechnik is a specialist and innovation leader in the development and production of automated complete solutions for sterile powder transfer. Our systems ensure the sterile state of the powder through the complete transfer chain from the spray dryer to the filling line.

The process vessels are equally used for transfer and mixing. In addition, cans, vessels, and bags can be docked to the filling line using our lift systems. Automating contamination-critical areas additionally increases the safety of employees and end users. ATEC offers the necessary know-how for each requirement and in all cleanroom classes to ensure the safe and sterile transfer of powder.

Application example: Powder transfer from the spray dryer to the isolator

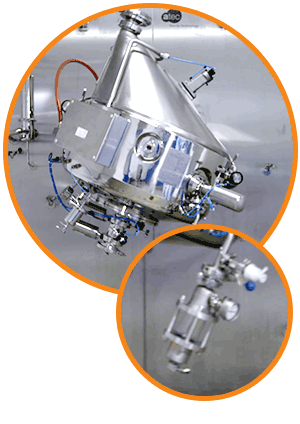

Powder is charged from the spray dryer into a sterile blending vessel.

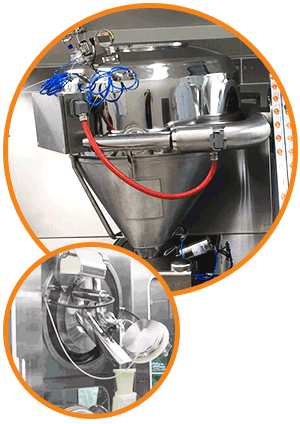

Powder blending and sampling take place at the blending station.

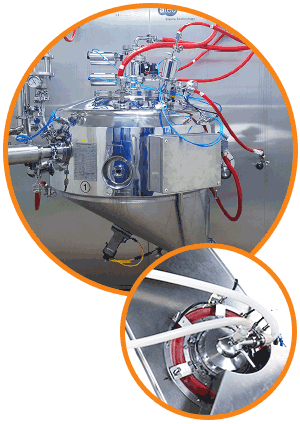

Powder transfer to the filling line is executed through a rapid transfer port.

CIP and SIP of the equipment is exectued at the blending station.

Video for the application example